Uma ufuna ukwenza iphansi elihle elingagugi (noma iphansi eliqinile elinokumelana nokungena kwamanzi elisezingeni eliphezulu), kufanele ubhekane namandla esisekelo sekhonkrithi, ikakhulukazi ukuba yisicaba. Iphansi elihle elingagugi alihlobene nje kuphela nekhwalithi ye-aggregate engagugi. Kudingeka indawo engcono yesisekelo. Leli phepha lihlose ukukunikeza ubuchwepheshe bephansi obuphelele nobuphelele bekhonkrithi kanye nobuchwepheshe bokumelana nokuguga. Okuqukethwe okulandelayo yizindlela zokwakha ezifingqiwe yiShanghai Jiezhou Engineering & Mechanism Co., Ltd. ngokweminyaka eminingi yesipiliyoni embonini. Njengereferensi yakho.

Inqubo yokwakha: ukwelashwa kwesisekelo sendlela → ukusetha ifomu lokugcina impahla → ukuphakelwa kokhonkolo → umshini wokulinganisa we-laser ukugandaya, ukudlidliza nokuhlanganisa → ukusabalalisa insimbi ehlanganisiwe → ukukhipha i-calendar kanye ne-slurry → ukupholisha → ukunisela nokulungisa → ukusika nokuhlanganisa ngomshini.

Isithombe sokwakhiwa kwe-laser screed

Ukwelashwa okuyisisekelo

1. Okokuqala, udoti oseceleni kufanele ususwe futhi kungabikho zindawo ezomile ebusweni besisekelo.

2. Hlanza ingxenye ephumayo yendawo ukuze ukuphakama kobuso kufane. Hlola ukuthi ukuthamba kwesisekelo kuyahlangabezana yini nezindinganiso ezingaphakathi kuka-± 2cm ukusuka ekuphakameni komklamo ukuqinisekisa ubukhulu bekhonkrithi.

Izilungiselelo zesifanekiso

Okokuqala, ngokuya ngesimo sekholomu yensimbi yesitshalo sonke, izidingo zomklamo, ukulungiswa kwefomu, isiqondiso sokuhamba kwemoto kanye nezici zokwakha zemishini yokulinganisa, kwakhiwa uhlelo lokuthulula oluthembekile lokwakha. Ifomu eliqinile kufanele lifakwe endaweni yokwakha. Ifomu kufanele libe ifomu elikhethekile elenziwe ngensimbi yesiteshi, futhi ukuvulwa okuphezulu kwefomu kufanele kulungiswe ukuze kwenziwe kube yisicaba futhi kuhambisane ngaphakathi nangaphandle.

Setha ungqimba olushelelayo

Ngemva kokumiswa kwefomu, indawo yokwakha kufanele imbozwe ngefilimu yepulasitiki ukuze ihlukanise isisekelo nobuso bekhonkrithi ukuze kwakheke ungqimba olushelelayo.

Ukubopha i-mesh yokuqinisa

1. I-reinforcement mesh kufanele icutshungulwe ngokuhlanganisa okuhlanganisiwe endaweni, bese ithuthwa iye endaweni ekhethiwe ukuze ibekwe ngemuva kokubopha. Indawo yokuqinisa kufanele ihlanzeke, ingabi nokungcola, ukugqwala, njll. ukuqinisekisa ikhwalithi yezinto zokusetshenziswa. I-reinforcement mesh kufanele iboshwe ngokuphelele, futhi isikhala nosayizi kuzohlangabezana nezidingo zomklamo kanye nemininingwane. Ngemva kokubopha, hlola i-reinforcement mesh ukuze ubone ukuthi ungqimba oluvikelayo lwanele yini, ukuthi i-binding iqinile yini nokuthi ikhona yini i-leasure.

2. Ngaphambi kokuthela ukhonkolo, kufanele ufakwe endaweni ekhethiwe yizisebenzi. Usayizi we-reinforcement mesh ngu-3M × 3m.

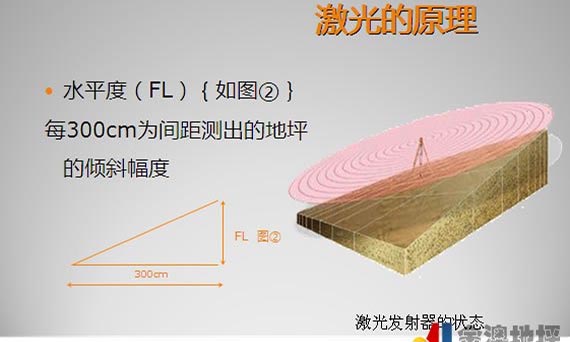

Ukufakwa komshini wokulinganisa i-laser

Ngaphambi kokuthulula ukhonkolo, umshini wokulinganisa i-laser kufanele ulungiswe. Misa futhi ulinganise umshini wokudlulisa i-laser, bese ulungisa izinga nokuphakama kwekhanda lokulinganisa lomshini wokulinganisa i-khonkolo ngokwesignali edluliselwe ukuze uhambisane nokuphakama komhlabathi wekhonkolo. Ngesikhathi esifanayo, lungisa umehluko wokuphakama kuzo zombili iziphetho zekhanda lokulinganisa ngaphakathi kuka-0.5mm. Ngaphambi kokwakha okukhulu, qala usebenzise imishini yokukhiqiza ukuhlola bese uhlola ukuqinisekisa ukuthi akukho phutha.

Ukuthululwa kukakhonkolo

1. Kuzosetshenziswa ukhonkolo wezohwebo. Ukusebenza kwenkonzo kakhonkolo wezohwebo kuzohlangabezana nezidingo zemininingwane efanele, futhi ukucwila kukakhonkolo efomini kuzolawulwa ku-160-180mm.

2. Ukhonkolo kumele ugandaywe kusukela ekugcineni ngendlela ehlelekile. Lapho ingxube yekhonkolo ithululelwa efomini, ukulayisha kufanele kugxile futhi kuhambe kancane, kanti ubukhulu obubonakalayo buzoba cishe ngamasentimitha amabili kunokhonkolo. Uma kudingeka, izinto kufanele zincishiswe noma zenezelwe, futhi izingxenye eziqondile nezivundlile kufanele zihlangabezane nezidingo. Ukhonkolo kumele ugandaywe njalo ngaphandle kokuphazamiseka.

3. Ngemva kokuba ukhonkolo usuthululiwe, izinqwaba zekhonkolo kumele zilinganiswe ngesandla ngaphakathi kwebanga elisebenzayo lengalo ye-telescopic yomshini wokulinganisa, bese ukudlidliza, ukucindezela kanye nokulinganisa kufanele kuqedwe ngesikhathi esisodwa ngomshini wokulinganisa we-laser. Enqubweni yokulinganisa, thatha uhlangothi olulodwa njengomgomo, bese ulala phansi kusukela ngaphakathi kuya ngaphandle isinyathelo ngesinyathelo.

4. Izindawo lapho ukwakhiwa kwemishini kungenzeki khona, njengamakhona nezinsika zensimbi, kufanele zihlanganiswe futhi zilinganiswe ngesandla.

Ukwakhiwa kwephansi okumelana nokuguga

Ngaphambi kokufakwa kokuqala kwekhonkrithi, i-disc trowel kufanele isetshenziswe ukuplasta kahle kuze kube yilapho i-slurry ikhishwa, bese i-hardener isatshalaliswa ngokulinganayo ebusweni bekhonkrithi. Ngemva kokuba i-hardener imunce inani elithile lamanzi, qala ukugaya; Ngemva kokugaya okuqinile, ungqimba lwesibili lwe-hardener kufanele lusakazwe, futhi inani lezinto kufanele libe yi-1/3 yalelo lenqubo yangaphambilini. Ukugaya okuphambene kufanele kwenziwe ngesikhathi sokugaya, futhi akukho ukugaya okulahlekile okuvunyelwe.

Ukuqiniswa nokupholishwa kwetrowel

1. Ngemva kokulinganisa nge-laser, ukhonkolo kufanele uphakanyiswe bese uqedwa nge-trowel ngaphambi nangemva kokusetha kokuqala. Ukusebenza kwe-trowel ye-disc grinder kufanele kwenziwe izikhathi eziningi ngokuya ngokuqina kwengqimba engaphezulu. Ijubane lokusebenza kwe-trowel yomshini kufanele lilungiswe ngokufanele ngokuya ngokuqina komhlabathi wekhonkolo, futhi ukusebenza kwe-trowel yomshini kufanele kwenziwe ngokuqondile nangokuvundlile.

2. Ngaphambi kokusetha kokugcina, shintsha idiski yomshini wokugaya njenge-blade, bese ulungisa i-engeli yokugaya nokupholisha. Ngokuvamile, umsebenzi wokupholisha uphindwe izikhathi ezingaphezu kwezimbili ukuze wenze i-floor gloss ifane.

Uqhekeko:Amajoyinti kufanele asikwe ngesikhathi esingu-2-3D ngemuva kokwakhiwa kwendlela engaphezulu engagugi. Ukusika okumanzi kufanele kusetshenziswe kumajoyinti okusika, anobukhulu obungu-5cm kanye nokujula okungenani i-1/3 yobukhulu bekhonkrithi. Umthungo wokusika kufanele uqonde futhi ube muhle.

Ukwelapha: Ngemva kokuba ukhonkolo usupholishiwe, kufanele umbozwe ngefilimu bese uniselwa ukuze uqine. Ngesikhathi sokuqina, lapho amandla ekhonkolo ebusweni engafiki ku-1.2MPa, akekho okufanele ahambe phezu kwawo.

Ukucaulking

1. Ngemva kokuba phansi sekulungisiwe amasonto amabili, hlanza kahle ilunga lokusika bese ususa zonke izinhlayiya ezikhululekile kanye nothuli oluselunganweni lokusika.

2. I-polyurethane sealant enokuqina okuhlala isikhathi eside kanye nokuqina okusheshayo kufanele isetshenziswe ukugcwalisa ijoyinti elinciphayo.

Izinyathelo zokulawula

1. Izinto ezisetshenziswa endaweni kumele zamukelwe endaweni, futhi kufanele zibekwe endaweni ekhethiwe ngemva kokudlula ukwamukelwa. Qaphela ukuthi izinto ezidinga amanzi kumele zithathe izinyathelo ezifanele zokulwa nomswakama nemvula.

2. Nikeza abasebenzi abanolwazi lokuphatha ukwakhiwa kanye nabasebenzi bokwakha abanekhono. Ngaphambi kokwakhiwa, abasebenzi abafanele kufanele bahlelwe ukuze benze ukudalulwa kobuchwepheshe ngokusetshenziswa okufanele kwemishini namathuluzi okwakha kanye nokulawulwa kwezinqubo ezibalulekile, ukuze kuqinisekiswe ukuthi abasebenzi bokwakha banekhono ekusebenzeni kwenqubo ngayinye.

3. Imishini yokwakha namathuluzi kufanele ahlangabezane nezidingo, abe sesimweni esihle, futhi alungiselele ezinye izinto ezibalulekile ezisele.

4. Indawo yokwakha kufanele igcinwe ihlanzekile futhi icocekile ukuvimbela uthuli nezinye izinto ezomile ukuthi zingangcolisi umhlabathi.

5. Amaphakethe, udoti kanye nezinye izinto ezilahliwe ezishiywe endaweni kufanele zisuswe nsuku zonke ukuqinisekisa ukuthi indawo iyasulwa ngemva komsebenzi. Uma kwenzeka izinto ezikhethekile ezilahliwe, indlela yokwelapha kufanele ihambisane nezidingo zokwelashwa kwezinto ezikhethekile.

Okokugcina, ngaphezu kokulandela ngokuqinile izinqubo ezingenhla, iphansi elihle elingagugi lidinga futhi ukubambisana nokubambisana phakathi kwekhonkrithi nephansi elingagugi.

Yasungulwa ngo-1983, iShanghai Jiezhou Engineering & Mechanism Co., Ltd. igxile ku-R&D, ukukhiqizwa kanye nokuthengiswa kwemishini emkhakheni wephansi likakhonkolo. Umshini wokusika nge-laser, i-power trowel, umshini wokusika, i-plate compactor, i-tamping rammer neminye imishini isebenzisa ubuchwepheshe bamuva futhi idunyiswa kakhulu ngamakhasimende.

Inamakhasimende emazweni angaphezu kwekhulu emhlabeni jikelele futhi ihola phambili embonini. Uma unemibuzo, ungashayela i-DYNAMIC, futhi sizokukhonza ngenhliziyo yonke!

Isikhathi sokuthunyelwe: Agasti-24-2022